PANDA Laser Marking

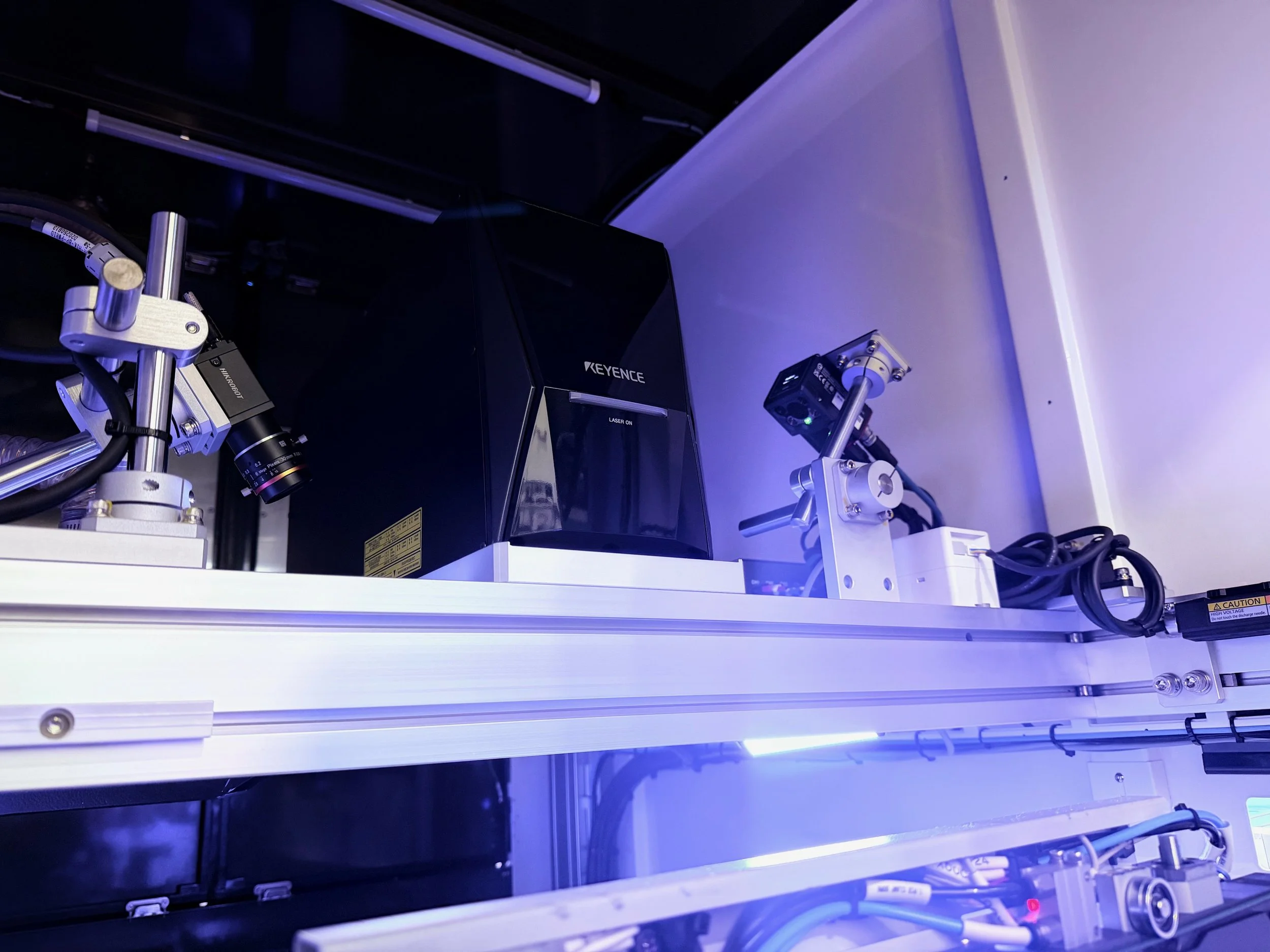

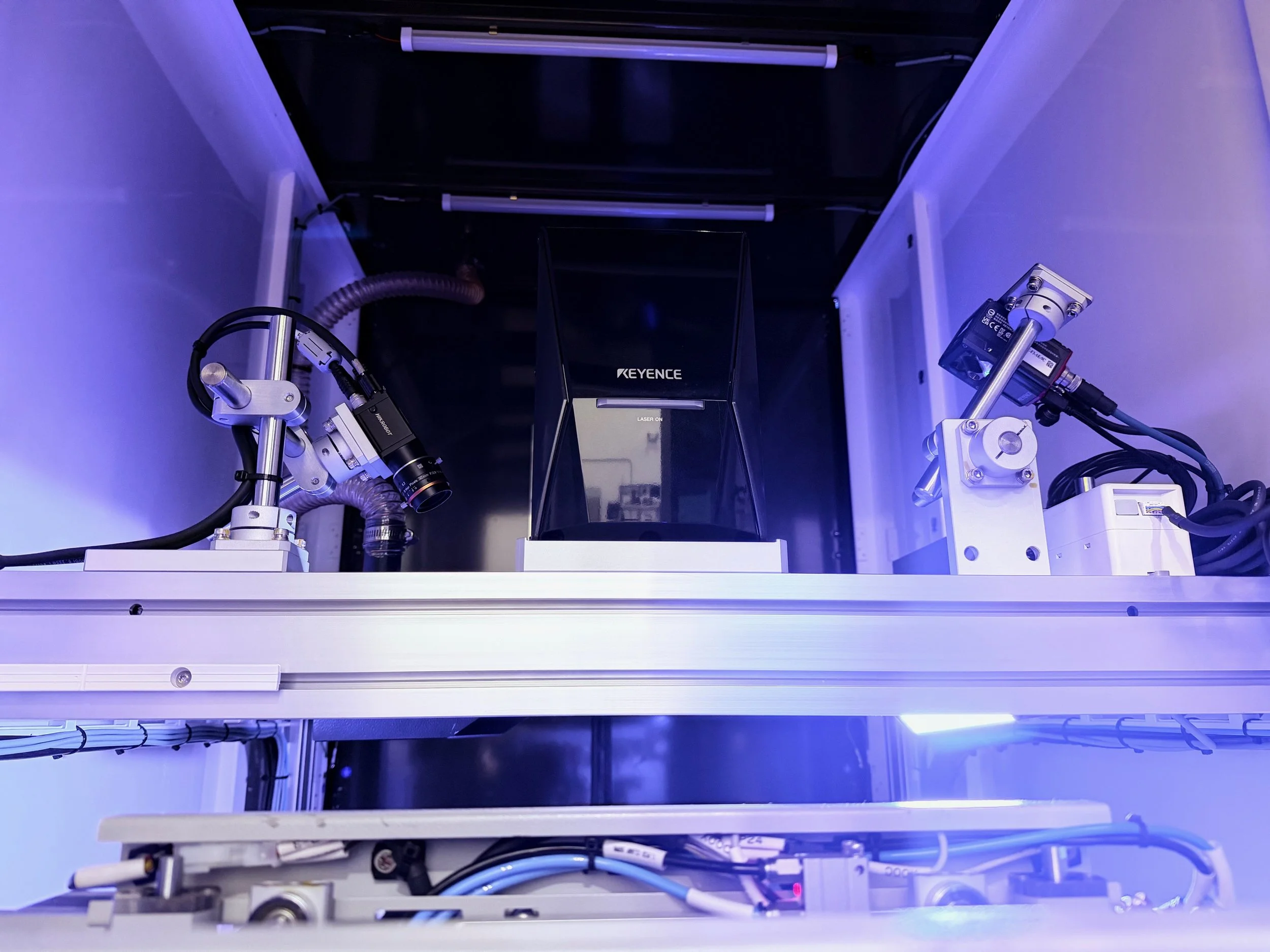

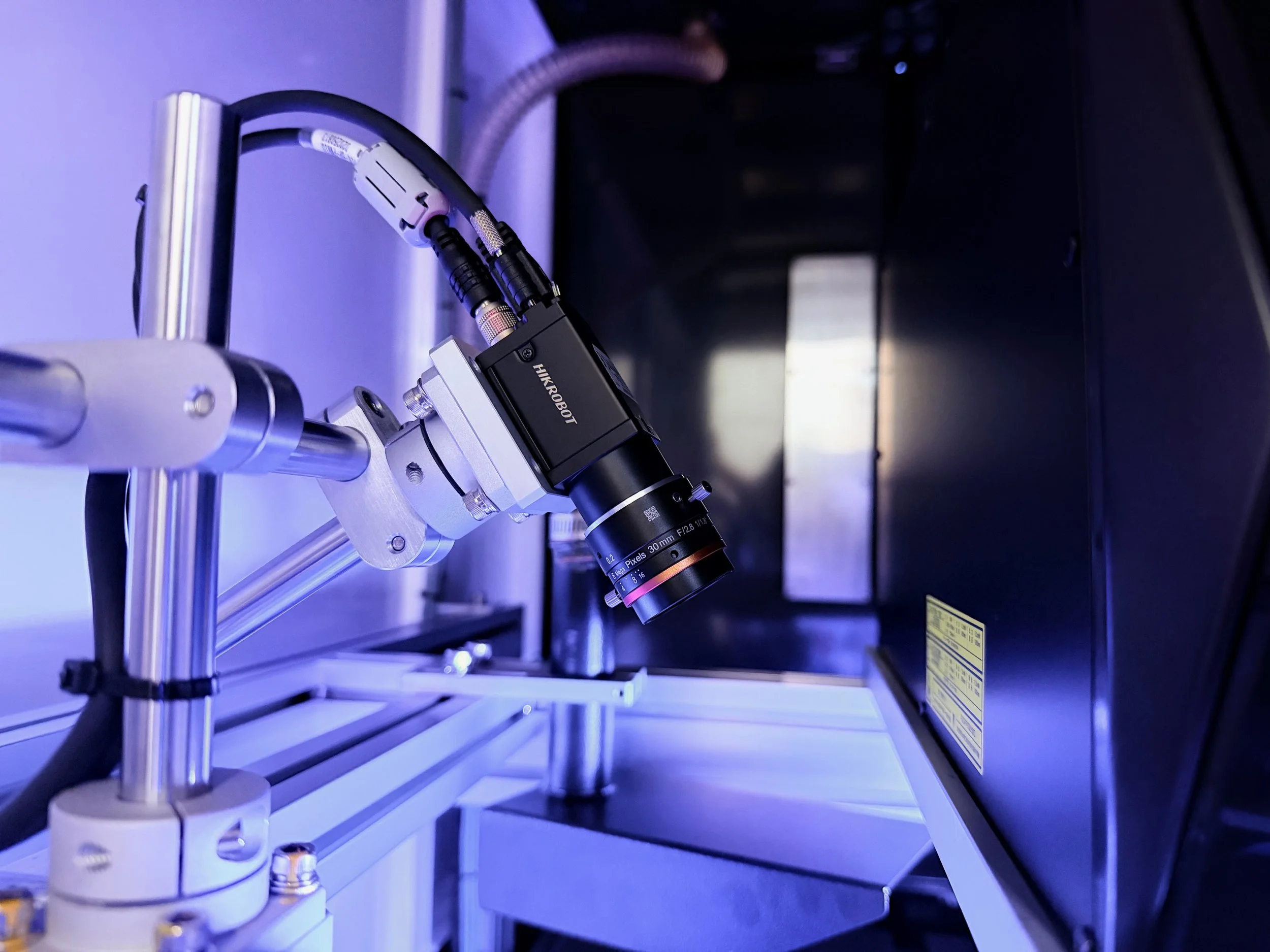

The All New Panda Laser Marking System is designed with the latest Laser Marking technologies for in-line production applications. Built on a rugged steel welded base, the system is packed with feature rich technology while continuing to maintain the lowest cost of ownership in its class. The Panda Laser Marking System utilizes a High Performance Keyence Laser Head with Integrated Fiducial Alignment, Vision Guidance and Vision Mapping Programming, Internet Based Remote Support Features, Full Network Capability, and offers a variety of technological upgrades.

Newly designed 460 Series Laser Marking Systems feature a 27” Touchscreen Interface, Discreet Keyboard Tray, and Sliding Glass front door are available on all LITE / EDGE / PRO Configurations.

Adaptive IQ + Technology features a 32” Touchscreen Transparent OLED: Available on 600 Series Equipment Only.

Standard Features Include:

CO2 (Lite), Hybrid (Edge), or UV (Pro) Laser Head Configurations Available

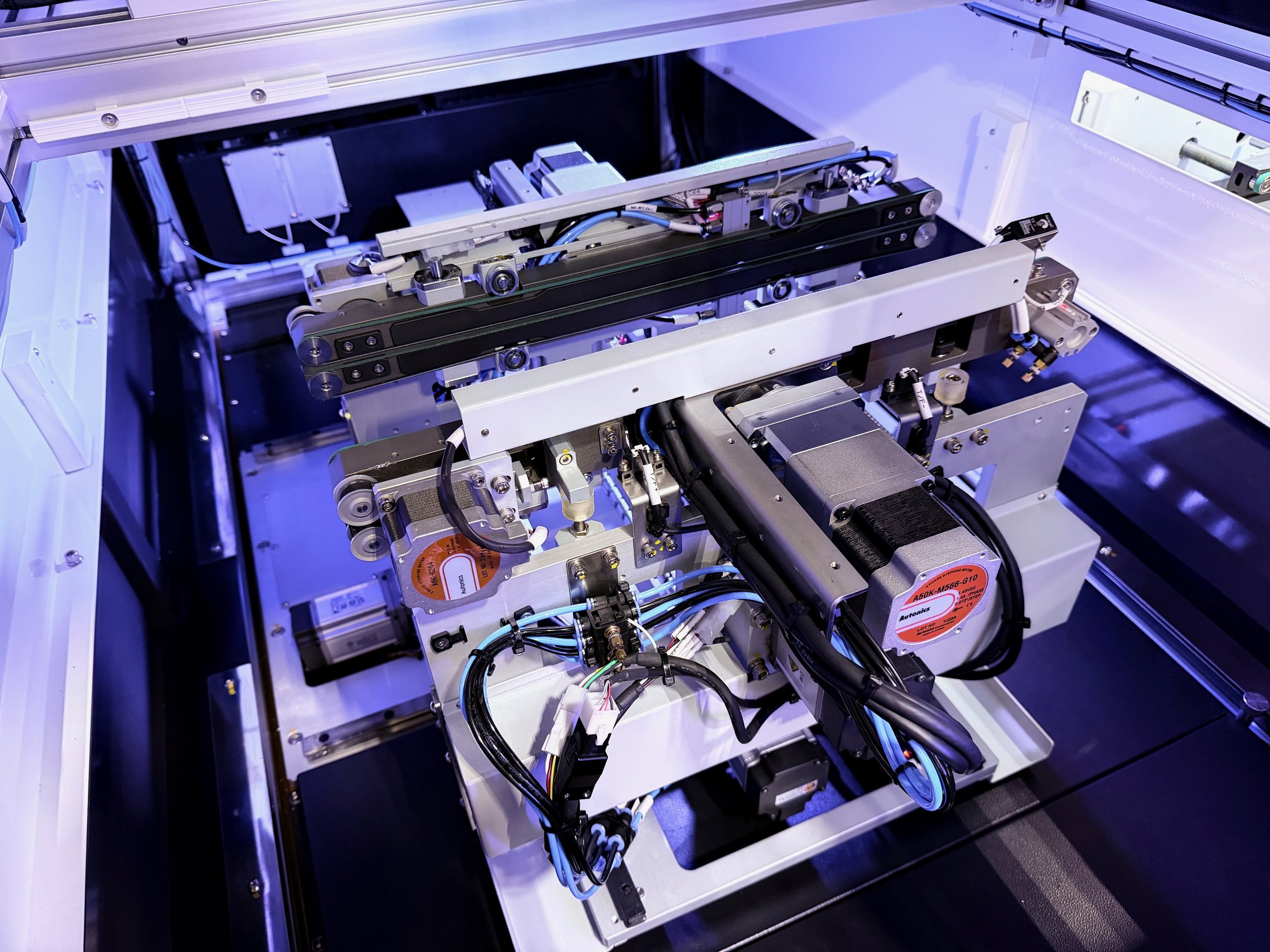

High-Speed Precision Gantry (+/- .01mm)

420mm x 420mm or 500mm x 500mm Motion Area

On-Screen Vision Assisted Programming

High Dynamic Vision Alignment System

Tri-Color LED Lighting

Symmetrical Array Programming

Master Offset of Marking Locations

Automatic Width Adjust up to 458 mm – High speed type

ESD Edge Belt Conveyor System (3mm edge contact)

- Custom Thin Belt or Heavy Duty conveyance solutions also available.Single Segment conveyor w/Dual Transport Speeds

Can accept at a slower speed for loose components

WIN11 PRO PC Operating System with Touch Screen Display

Multi-level Program Access (Password Protected)

High Resolution Process Witness Camera

On-Board Fume Extraction System

Localized Fume Extraction at Laser Head Level

Additional Options Available:

Adaptable MES Network Options and Configurations Available

Ionizing Air Blade System

PCB Orientation Validation

Log File Reporting / MES Ready

Maintenance Reminder Scheduling

Remote Technical Support – with Internet Connection

Optional Integrated Bar Code Scanner and Auto Recipe Load

Adaptive IQ+ Technology (Lite/Pro/Edge 610 Series Only*)