PANDA SOLDERING

The All New Panda System is designed with the latest soldering technologies for in-line production applications. Built on a rugged steel welded base, the system is packed with feature rich technology while continuing to maintain the lowest cost of ownership in its class. The Panda System utilizes a robust 180Watt Soldering System with Integrated Heated Nitrogen Output, Vision Guidance Programming, Internet Based Remote Support Features, full network capability, and Optional Barcode Scanner with Auto Recipe Selection.

2020 NPI AWARD WINNER

presented by Circuits Assembly Magazine

Standard Features Include:

High-Speed Precision Gantry (+/- .01mm)

500mm x 500mm Motion Area

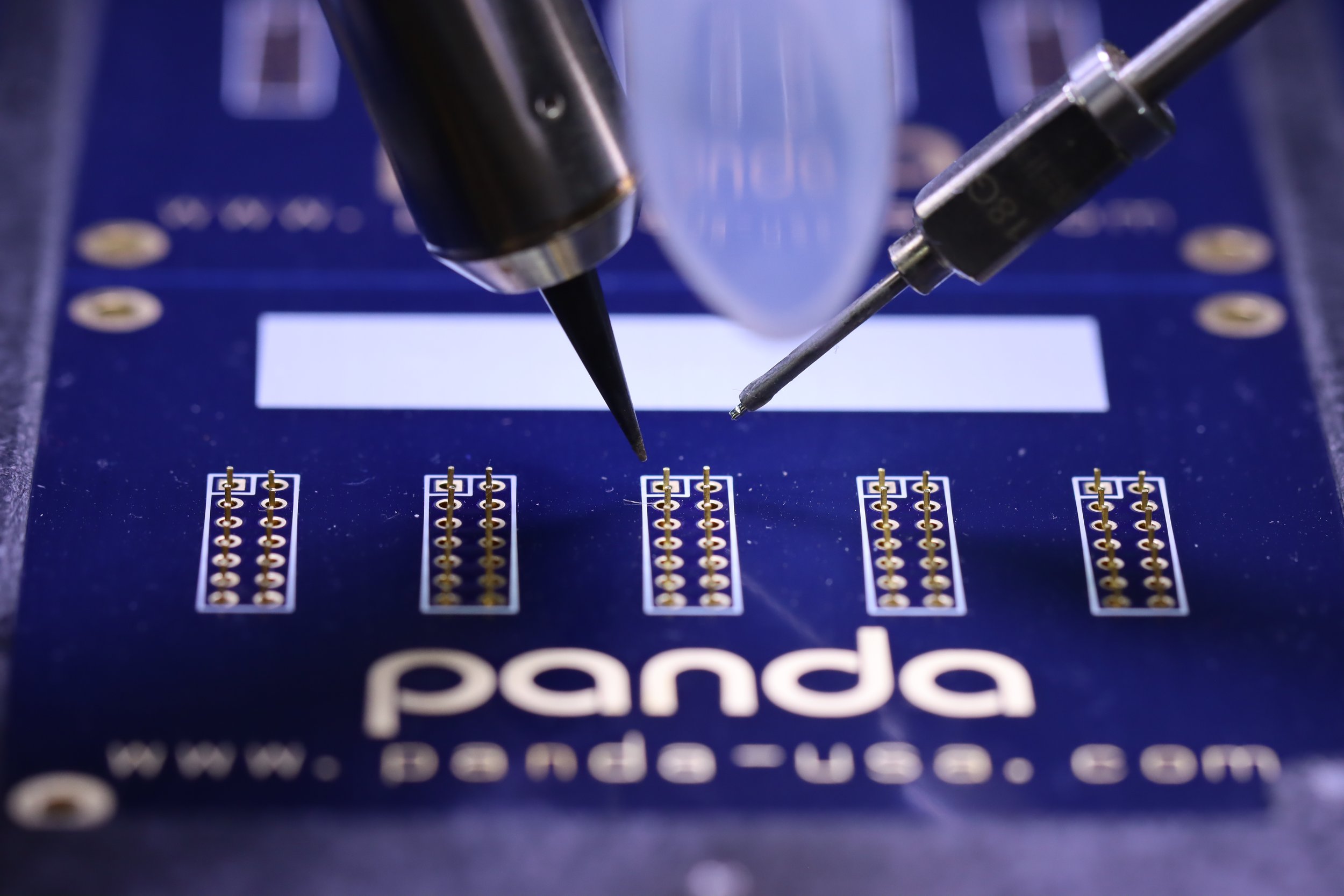

On-Screen Vision Assisted Programming / Vision Mapping

Dynamic Vision Alignment

Symmetrical Array Programming

Master Offset of Soldering Locations

Automatic Width Adjust up to 458 mm – High speed type

Pin Chain Conveyor System (5mm edge contact)

Single Segment conveyor w/Dual Transport Speeds

Can accept at a slower speed for loose components

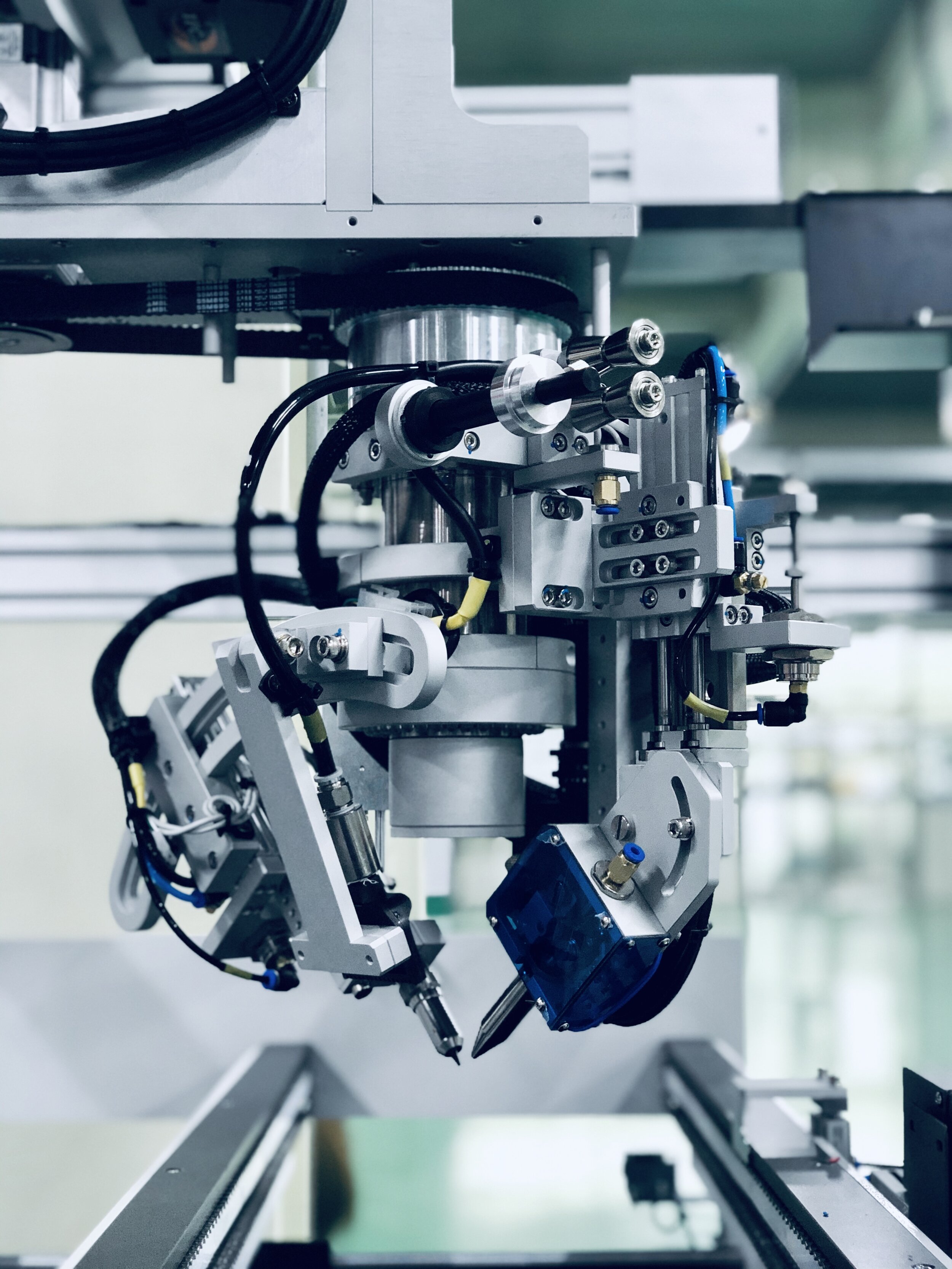

Re-designed soldering head

Independent Action Hot Iron / Solder Feeder

WIN10 PC Operating System with Touch Screen Display

Multi-level Program Access (Password Protected)

High Resolution Solder Process Witness Camera

On-Board Nitrogen Generation System

Heated Nitrogen at Soldering Location

On-Board Fume Extraction System

Localized Solder Fume Extraction at Solder Tip

Other Standards:

180-Watt Power Supply and N2 Ready Soldering Iron

(Curie Point Heating Technology)Dual Solder Tip Cleaning System (Air and Brass Brush)

Large Process Viewing LCD – Real-time Process Viewing

Fiducial Alignment

PCB Orientation Validation

Black Chrome Plated Solder Tips (Localized Reflow Area)

Log File Reporting / MES Ready

Maintenance Reminder Scheduling

Remote Technical Support – with Internet Connection

Optional Integrated Bar Code Scanner and Auto Recipe Load

VIDEO INTRODUCTION

Intelligent Soldering for the Premier Electronics Manufacturer

PANDA FEATURES AND SPECIFICATIONS:

FEATURES: ROBOT MODEL:

Panda Soldering Series

Construction: Welded Steel Frame Base / Extruded Aluminum

Exterior: Sheet Metal / Gray and White powder coat paint

Integrated Conveyor: Pin Chain / Single Segment

Variable Speed Controller – Dual Speed

Width Control: Automatic

Robot Type: Cartesian Gantry

Robot Motion Control: Servo / 0.01 mm

Moving Area:

X-Axis 500mm

Y-Axis 500mm

Z-Axis 150mm

R-Axis 380°

Moving Speed:

X-Axis 0-600mm/sec

Y-Axis 0-600mm/sec

Z-Axis 0-200mm/sec

R-Axis 0-300mm/sec

Working Area:

X-Axis 458mm

Y-Axis 458mm

Z-Axis 150mm

R-Axis 380ᵒ

Soldering Iron: (180 Watt) / 912 Type Tips

Solder Feed Station: Custom design / Wire grip type / Self guiding / 1 lb. spool

Teach Method: WIN10 PC / On-Screen Vision Assist

Program Storage: On-board Storage / Unlimited

Heat Source: 180-Watt

Black Chrome Solder Tips

50° ~ 500°C

Nitrogen: Assorted N2 Sleeves

On-board System

Heated Nitrogen at tip

Fume Extraction: On-board System

Localized at Tip

Process Viewing: HD Witness Camera w/On-screen viewing

Safety: NFPA79 and/or CE Compliant

Sliding Front Door / Panoramic Windows

Operating System: WIN 10 Pro

Tip Cleaning Method: Dual Tip Cleaning System (Air & Brush)

Product/Fixture Area: 75 mm W x 75 mm L ~ 458 mm W x 458 mm L

Product Location Method: Vision Mapping / Fiducial Alignment

Product Orientation Validation

Power Requirement: Dual 110V – 3 prong

Total Wattage: 3.7K W +/- 5%

Air Requirement: 72 PSI / Single Air Regulator / 8 mm hose

Overall Dimensions: 1250mm(L) x 1300mm(D) x 2127mm(H)

Communication: SMEMA 1.2

Pass Line Height: 950 mm +/- 50 mm

Work Cell Leveling: Roller Wheels

Leveling Feet